Executive Context

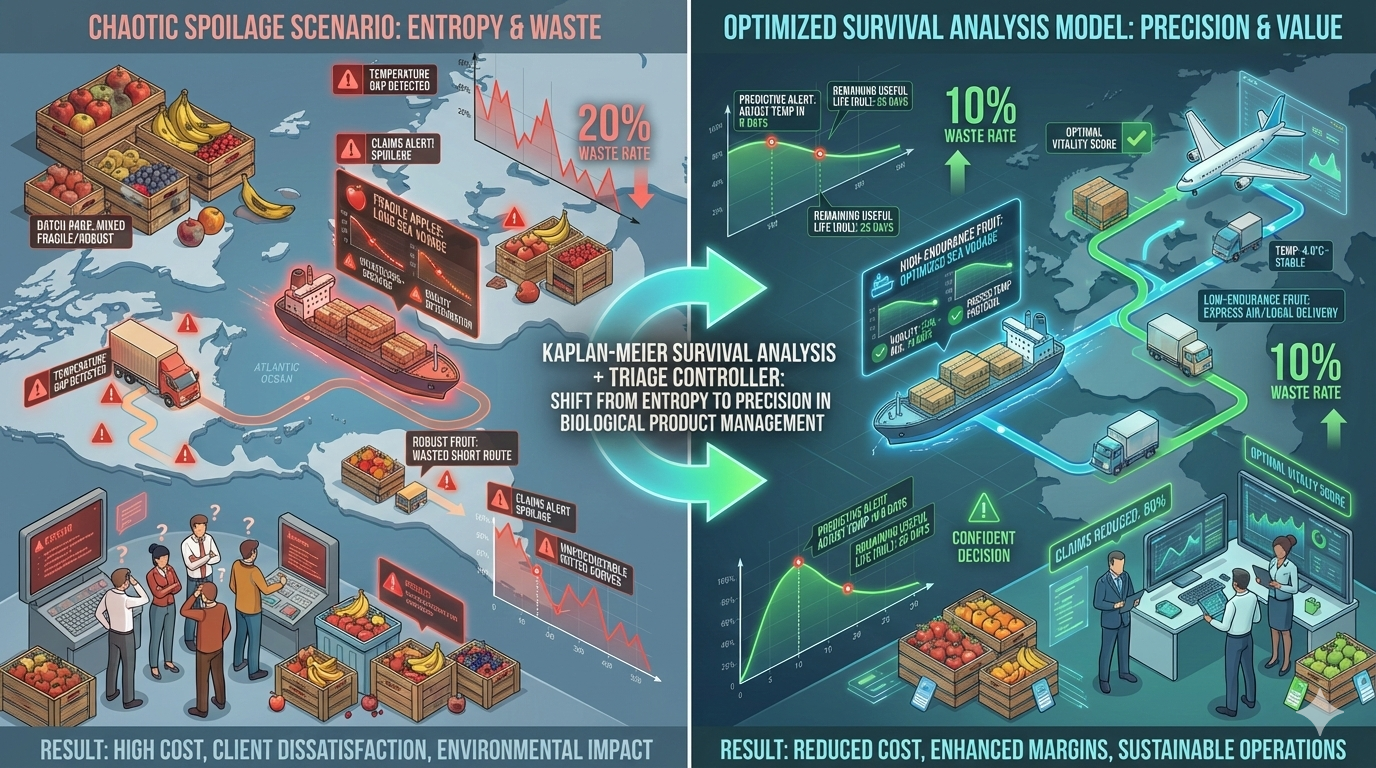

A global leader in the high-value fruit export market faced severe margin erosion due to “Claims” (spoilage and returns). Roughly 20% of their annual yield was lost to degradation during the seed-to-shelf logistics journey.

The operational constraint was entropy. Because the organization could not predict when a specific harvest batch would spoil, they allocated inventory randomly—sending fragile batches on long sea routes and robust batches to local markets. This resulted in massive waste and unpredictable P&L swings.

The Actual Problem

While the stated problem was “Quality Control,” the underlying economic issue was pricing biological variance.

The organization was attempting to solve a Survival problem (Time-to-Failure) with a Classification tool (Good/Bad). Standard regression models treated the fruit as static widgets, failing to account for the non-linear decay curves driven by harvest conditions and temperature history.

They were trying to predict if it would rot, rather than when.

Diagnostic Approach

We treated the inventory not as products, but as patients in a clinical trial.

- Data Sufficiency: The client tracked harvest data, but it was aggregated. We needed specific “vitals” (sugar, firmness, temp) for individual batches.

- Methodological Fit: We identified Survival Analysis (Kaplan-Meier estimates)—standard in Oncology and Manufacturing Warranties—as the correct mathematical framework.

- Infrastructure Readiness: The logistics team lacked a mechanism to route inventory based on “Health Scores.”

Strategic Intervention

We re-architected the supply chain logic around the concept of “Remaining Useful Life.”

1. Survival Analysis Modeling

We trained Time-to-Event models on historical harvest and temperature data. This generated a specific “Survival Curve” for every batch, predicting exactly how many days it would remain viable under different storage conditions (35°F vs 42°F).

2. The Routing Optimizer

We built a “Triage Controller.” The system automatically matched high-endurance batches to high-risk, long-haul sea routes, and low-endurance batches to low-risk, air-freight or local routes.

3. Protocol Specification

The analysis revealed critical temperature thresholds for specific variants (e.g., Premium vs. Standard), allowing the client to adjust cold-chain protocols to extend the life of high-margin stock.

Outcome & Attribution

Aligning logistics to biological reality delivered immediate P&L expansion.

| Metric | Pre-Intervention | Post-Intervention | Impact |

|---|---|---|---|

| Claims Rate | 20% of Yield | 10% of Yield | 50% reduction in waste |

| Net Margin | Baseline | +15% Expansion | YoY Profit Growth |

| Revenue Lift | Baseline | +5% Growth | Improved availability |

| Prediction | Random / Average | Batch-Specific | Removed allocation guesswork |

Strategic Takeaway for Executives

You cannot optimize a supply chain if you don’t know the expiration date of your assets. By applying Survival Analysis (Oncology Math) to agriculture, we turned “Spoilage” from a random variable into a managed expense.

For enterprise leaders: The math must match the physics. If your product decays, your model must measure time, not just classification.

Open for confidential dialogue regarding perishable supply chain and margin optimization.